-

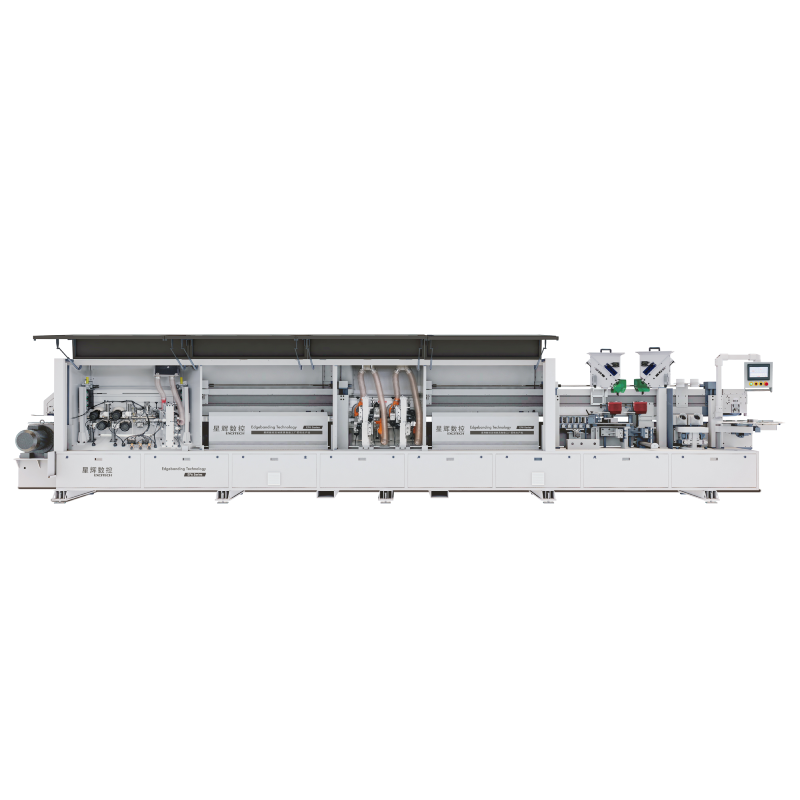

Condition: New

-

Type: Edge Banding Machine

-

Brand Name: Excitech

-

Voltage: 380V/450V

-

Dimension(L*W*H): 9580*1700*830mm

-

Weight (KG): 4100 kg

-

Applicable

Industries: Building Material Shops, Manufacturing Plant, Construction

works , Energy & Mining, Other, plywood machinery

-

Warranty: 1 Year

-

Function: Corner Trimming

-

Key Selling Points: Easy to Operate and durable

-

Panel Feed Speed(m/min): 32m/min

-

Video outgoing-inspection: Provided

-

Warranty of core components: 1 Year

-

Core Components: Bearing, Motor, Pump, Gear, PLC, Gearbox, Pressure vessel, Engine

-

Usage: Plywood Production, Funiture Panel Edge Banding

-

Product name: Wood Saw Wood Cut

-

Keyword: Precision Wood Cutting Sliding Table Saw Machine

-

After-sales Service Provided: Service Machinery Overseas

-

Table Size: 4300*4300*120mm

-

Saw Spindle Diameter: 450*60*4.8mm

-

Safe cutting Speed: 120m/min

-

After Warranty Service: Service

-

Color: Customer Actual Requirements

-

Cutting material: Nature Wood

Professionally

promote the informationization, intelligence and unmanned construction

of the furniture industry. The combination is flexible, the process is

changeable, and an automated production mode that meets the needs of the

customer's entire plant is created. Combine CNC nesting machine with

return conveyor to improve the automation level of the factory, get rid

of the dependence on workers, and effectively improve management

efficiency and production efficiency.

The panel is transmitted

through return conveyors, which is convenient for the follow-up

work. The designing software is optional according to the customer's

requirement.

Utilize the advantages of combining software and

automation equipment, it can form mass production, thereby achieving

automation production, reduce labor costs and increase production

capacity.

Advantage:

-

The first project successfully implemented by Chinese machinery manufacturer.

-

No

operator required for production rocedures. Labor cost and managing

overheads are therefore greatly reduced, so is production error.

-

Uninterruped

production with automatic machines enables furniture makers to add

extra shifts with minimum extra costs and concerns. The efficiency is

also increased by at a least 25 % compared to manual operation.

-

Smarter,

more cost-efficient production, quicker delivery and better quality

allow furniture makers for further expand production and sales,

achieving higher return on capital and property.

-

More individual products for end-users.